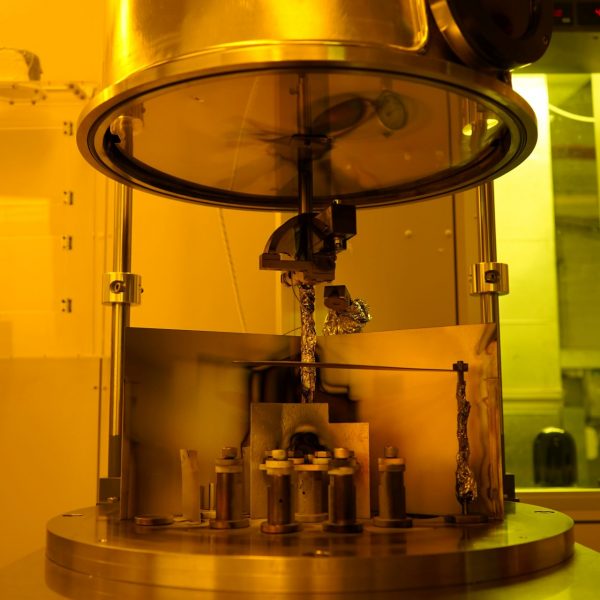

| Purpose | A thin-film deposition tool that deposits Al2O3 and HfO2 via sequential, self-limiting process cycles with precise thickness control |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Thermal, plasma, and ozone processes |

| Scale / volume | Small pieces up to 6 inch substrates |

| Specs / resolution | Specified to be able to deposit nitrides; techniques include thermal, plasma, and ozone processes; low temperature deposition process with uniform and conformal films |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Thin Film Deposition

Atomic Layer Deposition Picosun R200 *

CNT Savannah S200 atomic layer deposition system

| Location | UNSW – West Lab (White Area) |

| Materials | AlOx |

| Temperature range | 80 – 280C |

| Wafer size | Small chips up to 6” |

| Precursors | H2O, TMA |

| Restrictions | General purpose |

E-Beam Thermal Evaporator AJA ATC-1800-E *

| Purpose | A thin film deposition tool using e-beam or thermal process to deposit metal and oxides at nanometer scale thickness |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available materials include Ag, Al, Au, Cr, Ge, Ni, Ti, SiO2, TiO2, Ta2O, and Pt |

| Scale / volume | Small pieces to 6 inch substrates |

| Specs / resolution | Angled deposition capability; cooled rotating substrate holder; in-situ ion milling with Argon; controlled oxidation capability |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Edwards Auto 306 Thermal Evaporator (Aluminum SET)

| Location | UNSW – Lower East Lab (White Area) |

| Thin film material | Aluminium only |

| Gas | Oxygen, upper chamber for oxidation of Al only |

| Sample size | Up to 1 inch diameter (upper chamber) |

| Substrate material restriction | silicon compatible material only |

Edwards Auto 306 Thermal Evaporator (AuBe)

| Location | UNSW – Lower East Lab (White Area) |

| Thin film material | AuBe, Ti, Au |

| Base pressure | 9e-7 mbar |

| Sample size | Up to 3 inch in diameter |

| Substrate material restriction | Gallium arsenide compatible material only |

Edwards Evaporator

| Location | UNSW – South Lab (Test Area) |

| Maximum wafer size | 150 mm round |

| Throw | 400 mm |

| Boat contact size | 3/8” (~10 mm) |

| Maximum number of evaporator sources | 4 |

| Maximum power | 250 W |

| Additional process gases available | Ar, O2 |

| Other specifications | Glow discharge of process gases |

Lesker Thermal Evaporator

| Location | UNSW – South Lab (Test Area) |

| Thin film material | Ge, Ni, Ti, Au, AuGe, PdAu, Cr, Al, Co |

| Base pressure | 9e-7 mbar |

| Sample size | Up to 3 inch in diameter |

| Rotation | Angled evaporation with rotation |

Lamp Annealer ULVAC MILA 5000 *

| Purpose | A desktop annealer capable of delivering high speed heating and cooling |

| Location | Wet Etch Bay, RPF Cleanroom |

| Material systems | Gases available N2 and forming gas |

| Scale / volume | Maximum wafer size 20mm x 20mm |

| Specs / resolution | Maximum temperature of 1000°C; 50°C/s high speed heating |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Parylene Coater

| Location | UNSW – South Lab (Test Area) |

| Sample type | ALL (but contamination or hazardous ones) |

| Sample size | Up to 6” wafer (4 tiers substrates holder) |

| Adhesion promoter | Silane A-174 |

| Thickness range | 100 nm to 10um

(Thicker layer on request) |

| Dimer type | Parylene C |

Picosun R-200 ALD system

| Location | UNSW – West Lab (White Area) |

| Materials | HfO2 and Al2O3 |

| Substrate | Small chips to 200mm |

| Temperature Range | 100C – 500C |

| Precursors | H2O, TMA and TEMAH |

Sputter Coater DC Emitech K550

| Purpose | A small DC sputtering tool that can coat metal onto substrate |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available metal targets include Au, Ti, and Ni |

| Scale / volume | Small pieces to 6 inch substrates |

| Specs / resolution | Multiple small substrates for coating; coating uniformity up to 3.5 inch diameter |

Sputterer AJA ATC-2000-UHV *

| Purpose | A 5-gun DC/RF sputtering system that deposits metal and oxides at a controlled angstrom per second rate |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available materials include NbTi(N), SiO2, TiO2, ITO, Al, and Ti |

| Scale / volume | Small pieces to 6 inch substrates |

| Specs / resolution | Base pressure lower than 5 x10-8 torr; in-situ ion milling available; RF biased sample pre-clean available; substrate rotation with heating up to 800oC; ion milling / assisted deposition with Argon; controlled oxidation or nitration capability |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Tystar Mini-Tytan Horizontal 3 Stack LPCVD Furnace System

| Location | UNSW – East Lab (Grey Area) |

| Max capacity | 50 x 8” wafers per run, though typically 25 x 6” or 4” |

| Tube #1 | Stoichiometric and Low-Stress nitride |

| Tube #1 gases | Dichlorosilane (DCS), Ammonia (NH3), Nitrous Oxide (N2O) |

| Tube #2 | P-doped or intrinsic polysilicon, amorphous silicon, dry oxide, low temp oxide P-doped or undoped. (Dopant gas currently unavailable) |

| Tube #2 gases | Silane (SiH4), Boron Trichloride (BCl3), Oxygen (O2) |

| Tube #3 | N-doped or intrinsic polysilicon, amorphous silicon, dry oxide, low temp oxide P-doped or undoped. (Dopant gas currently unavailable) |

| Tube #3 gases | Silane (SiH4), Phosphene (PH3), Oxygen (O2) |

| Temperature range | 400C – 950C (recipe dependent) |

| Pressure range | 100 mTorr – 500 mTorr |

Lesker PVD75 e-beam evaporator - Si-MOS compatible

| Location | UNSW – West Lab (Grey Area) |

| Sample type | Silicon Only – Si-MOS Compatible |

| Sample size | Up to 4” wafer |

| Material available | Ti, Al, Pt and Pd |

| Thickness range | 1nm to 500nm |

| Option | Plasma clean capability by Ar sputtering |

Lesker PVD75 e-beam evaporator - general purpose

| Location | UNSW – West Lab (Grey Area) |

| Sample type | ALL (but contamination or hazardous ones) |

| Sample size | Up to 6” wafer |

| Material available | Metals: Ag, Al, Au, Co, Cr, Cu, Fe, Ge, Ir, Nb, Ni, NiFe, Pd, Pt, Si, Sn, Ti

Oxides: Al2O3, CeO2, Fe2O3, In2O3, SiO2, TiO2, WO3 Other materials by prior approval |

| Thickness range | 1nm to 500nm (Thicker layer on request) |

HHV sputtering system

| Location | UNSW – West Lab (Grey Area) |

| Sputter gases | Ar, N2, O2 |

| Target materials (3” targets) | Ti, Al, Cr, Au, Cu, W, Nb, Ag, Si, ITO, Si3N4, SiO2, TiO2, ZnO |

| RF power | 600W max |

| 2000W max | |

| Chamber heating | Room Temp to 400 |

| Max sample size | 6” |

| Base pressure | Mid 10-8 mtorr |

Oxford Instruments Plasmalab 100 plasma-enhanced chemical vapour deposition system

| Location | UNSW – Upper East Lab (Grey Area) |

| Materials | SiO2, SiN, a-Si:H |

| Temperature range | 100 – 300C |

| Wafer size | Small chips up to 6” |

| Gasses | SiH4, NH3, N2O, N2, Ar, CF4 |

| Restrictions | no metals |