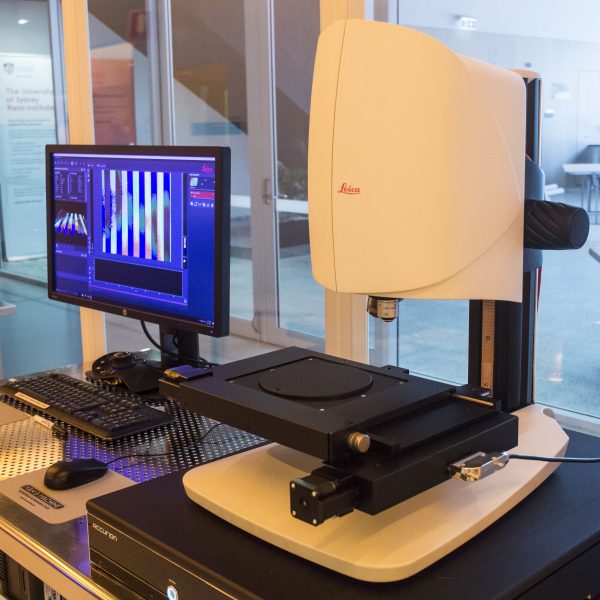

| Purpose | A metrology tool that leverages four optical modalities to image 3D topology and thin film/s properties with high automation |

| Location | Metrology Bay, RPF Cleanroom |

| Scale / volume | This microscope can accommodate samples up to 150mm diameter and 20cm in height, 3D topology mapping is limited to within a 40mm Z-range. |

| Specs / resolution | 3D topography can be mapped at a resolution down to ≈300nm in the XY plane and less than 1 nm in Z; modalities consist of confocal, three variants of interferometry, focal plane mapping, and reflectometry |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

All Equipment

3D Microscope Leica DCM8 *

3D Printer – Filament Flashforge Creator Pro *

| Purpose | 3D printing of low temperature flexible materials |

| Location | RPF Madsen Lab 224A |

| Material systems | For printing Thermoplastic Polyurethane (TPU), plus other soft and flexible materials |

| Scale / volume | Maximum build area of 227mm x 150mm x 148mm |

| Specs / resolution | 120°C heating build plate; double nozzle design; has the ability to print preforms with complicated structures and then draw those into fibre whilst maintaining that structure |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

3D Printer – Filament Funmat *

| Purpose | The Funmat HT 3D printer is fully capable of 3D printing high-performance functional materials like PEEK, ULTEM and PPSU, in addition to a broad range of engineering thermoplastics |

| Location | RPF Madsen Lab 224A |

| Material systems | Advanced thermal system design of this 3D printer includes a 90°C constant temperature chamber, up to 160°C heated build plate, and 450°C high-temperature extruder with all-metal hot end |

| Scale / volume | Build volume of the FUNMAT HT is 260mm x 260mm x 260mm |

| Specs / resolution | Users can achieve down to 50 micron high resolution industrial quality 3D printing |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

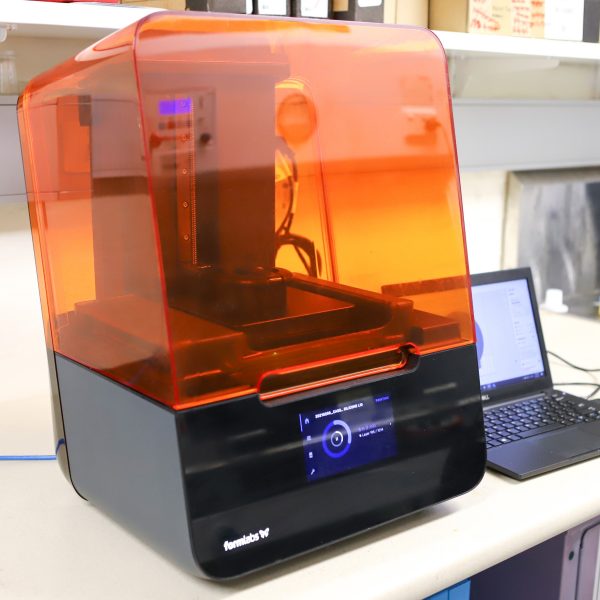

3D Printer – Resin Formlabs *

| Purpose | The Formlabs 3B SLA printer has been optimised for biocompatible materials |

| Location | RPF Madsen Lab 224A |

| Material systems | Biocompatible materials |

| Scale / volume | Build volumes of up to 14.5cm x 14.5cm x 18.5cm |

| Specs / resolution | Uses a flexible resin tank and a Light Processing Unit to produce consistent, accurate prints with X-Y resolution of down to 25µm; able to rapidly produce incredible surface finishes and high accuracy parts |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

4-point Probe

| Location | UNSW – Upper East Lab (White Area) |

| Substrates types allowed | Any |

| Substrate sizes | 30 mm x 30 mm to 2” |

| Probes | Four-point probe |

| Output | Sheet resistance for given current |

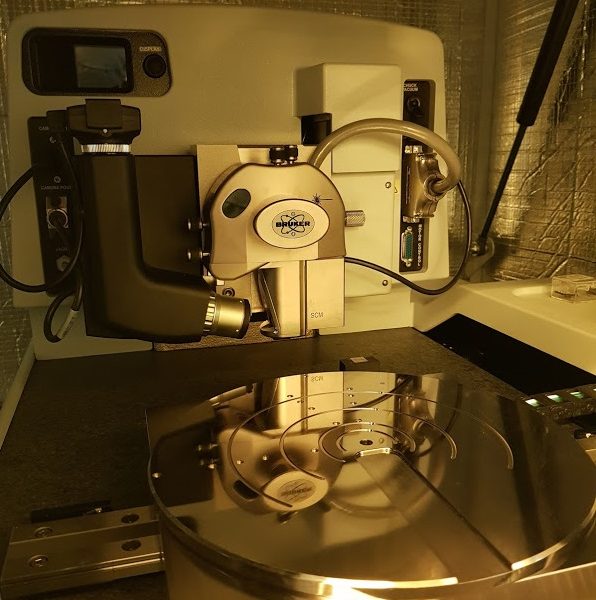

Atomic Force Microscope Bruker Icon *

| Purpose | A metrology tool that measures micron to sub-nanometre surface topology and material properties with nanometre sharp mechanical probes |

| Location | Metrology Bay, RPF Cleanroom |

| Scale / volume | This tool can accommodate 200mm wafers; maximum imaging area is 90 x 90 µm with a maximum Z-range of 10 µm |

| Specs / resolution | The resolution limit is dependent on sample and technique though generally on the order of few nm in XY and below 1nm in Z; many properties can be measured / investigated including topology, conductivity, capacitance, modulus, adhesion, etc. |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

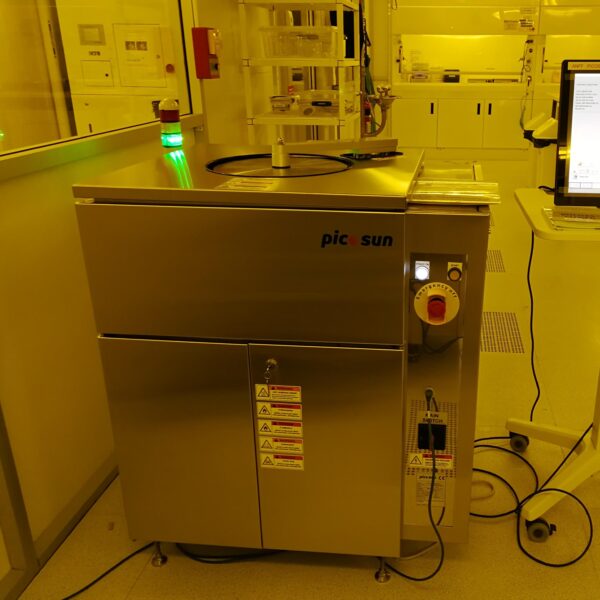

Atomic Layer Deposition Picosun R200 *

| Purpose | A thin-film deposition tool that deposits Al2O3 and HfO2 via sequential, self-limiting process cycles with precise thickness control |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Thermal, plasma, and ozone processes |

| Scale / volume | Small pieces up to 6 inch substrates |

| Specs / resolution | Specified to be able to deposit nitrides; techniques include thermal, plasma, and ozone processes; low temperature deposition process with uniform and conformal films |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Boron Diffusion Furnace

| Location | UNSW – Upper East Lab (Grey Area) |

| Temperature range | 750 – 975 °C |

| Substrates types allowed | Si wafer, with either P or B dopants only |

| Substrate sizes | Up to 2” |

| Pre-requisites | Wafers processed in-house only, full cleaned |

| Gases available | N2 |

| Source wafers | Solid source |

Bruker Dektak XT Stylus Profiler

| Location | UNSW – East Lab (White Area) |

| Measurement Capability | Two-dimensional surface profile measurements; Optional three-dimensional measurement/analyses |

| Sample X/Y Stage | Manual 100 mm (4 in.) X/Y, manual leveling; Motorized 150 mm (6 in.) X/Y, manual leveling |

| Data Points Per Scan | 120,000 maximum |

| Max. Sample Thickness | 50 mm |

| Step Height Repeatability | 4Å, 1 sigma on steps ≤1 μm (30 scans using a 12.5 μm stylus) |

| Vertical Range & Resolution | 1 mm, 1Å (@ 6.55 μm range) |

Bruker Dimension Edge AFM

| Location | UNSW – Lower East Lab (White Area) |

| X-Y Scan Range | 90μm x 90μm typical, 85μm minimum |

| Z Range | 10μm typical |

| Vertical Noise Floor | <50pm RMS |

| Sample/Size/Holder | 150mm vacuum chuck, 15mm thick |

| Scanning modes | ScanAsyst, Tapping, Contact |

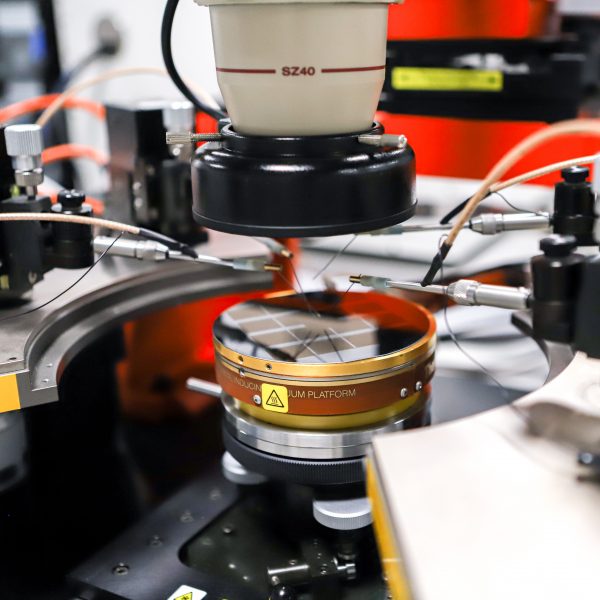

Cascade Probe Station

| Location | UNSW – South Lab (Test Area) |

| Model | Keithley Semiconductor Characterization system (4200SCS/C) |

| Available options | CV unit (4210-CVU),

Remote Preamp Option (4200-PA), Medium power SMU x 2 (4200-SMU), SMA to SSMC Dual with Local Ground (4200-PRB-C) |

Caustic Develop Wet Bench (ReynoldsTech)

| Purpose | Exhausted wet bench used for handling of caustic based chemicals – primarily TMAH based developers |

| Location | Wet Etch Bay, RPF Cleanroom |

| Material systems | Wafers and/or photomasks; TMAH based developers |

| Scale / volume | Substrates up to 7 inch square in size |

| Specs / resolution | Includes automated spin and spray process unit for development of substrates |

Chromium Etch Wet Bench (ReynoldsTech)

| Purpose | Exhausted wet bench used for handling of chromium etch chemicals |

| Location | Wet Etch Bay, RPF Cleanroom |

| Material systems | Photomask (chromium etch process); substrate (etch chromium structures) |

| Scale / volume | Etch substrates up to 7 inch square in size |

| Specs / resolution | Includes automated spin process unit |

Clean Anneal Furnace

| Location | UNSW – Upper East Lab (Grey Area) |

| Temperature range | 350 – 500 °C |

| Substrates types allowed | Si wafer, with either P or B dopants only |

| Substrate sizes | Up to 4” |

| Pre-requisites | Wafers processed in-house only, full cleaned |

| Gases available | N2, forming gas |

Clean Si Oxidation Furnace

| Location | UNSW – Upper East Lab (Grey Area) |

| Tube size | 5” tube |

| Wafer size | 2” up to 4” wafers |

| Gasses | N2, O2 |

| Temperature range | 400 – 1100C |

| Restrictions | Boron and phosphorus doped Si only |

CNT Savannah S200 atomic layer deposition system

| Location | UNSW – West Lab (White Area) |

| Materials | AlOx |

| Temperature range | 80 – 280C |

| Wafer size | Small chips up to 6” |

| Precursors | H2O, TMA |

| Restrictions | General purpose |

Coater Brewer Science CB-200

| Purpose | Spin coater for non-photo-sensitive polymer coating and baking of small samples |

| Location | RPF Lab 3021 |

| Material systems | Any material |

| Scale / volume | Can fit in up to 8 inch round wafer and 6 inch square substrate |

| Specs / resolution | The system has proximity, contact and vacuum contact baking capability |

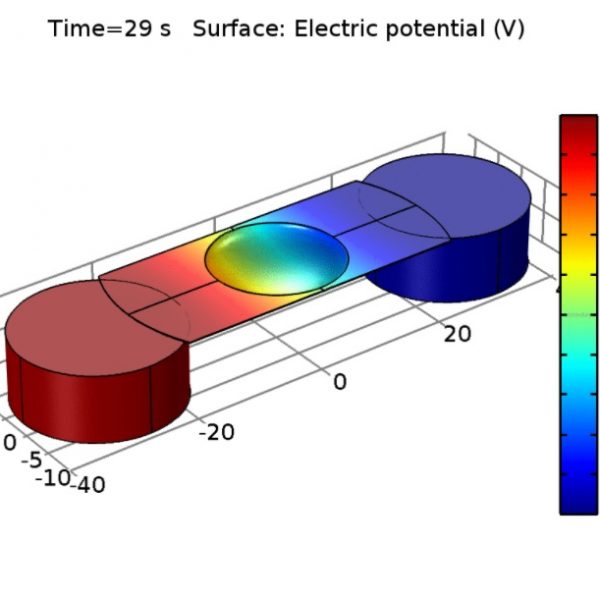

COMSOL Multiphysics

| Access mode | Remote via VPN |

| License | CPU locked |

| No of seats | 1 |

| Version | 5.1 |

| Available modules | AC/DC Module MEMS Module RF Module Wave Optics Module Heat Transfer Module Semiconductor Module Structural Mechanics Module Chemical Reaction Module Microfluidics Module Electrochemistry Module Material LibraryLivelink for MATLAB and AutoCAD |

| Hardware spec | 1500W power supply, Intel Xeon E5-2697V3 14 Core 2.6GHz CPU (x 2), DDR4 LRDIMM 32G (x 8), Leadtek quadro k620 2GB |

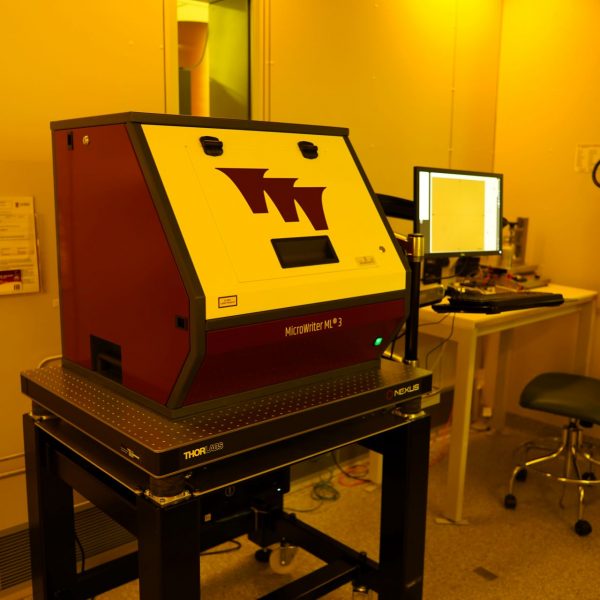

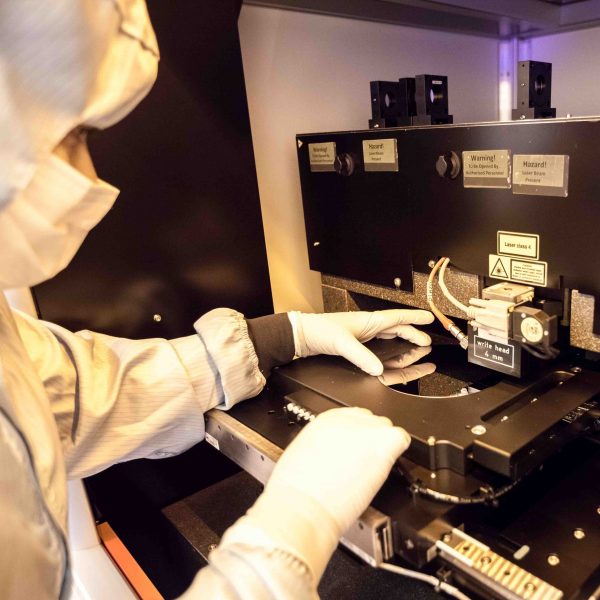

DMO MicroWriter ML3 Pro

| Location | UNSW – Upper East Lab (White Area) |

| Wafer sizes | Up to 200 mm by 200 mm, 15 mm max. thickness |

| Light source | 365nm |

| Avail. resolutions | 0.5 µm, 0.7 µm, 1 µm, 2 µm and 5 µm at 365 nm |

| Greyscale levels | 256 levels |

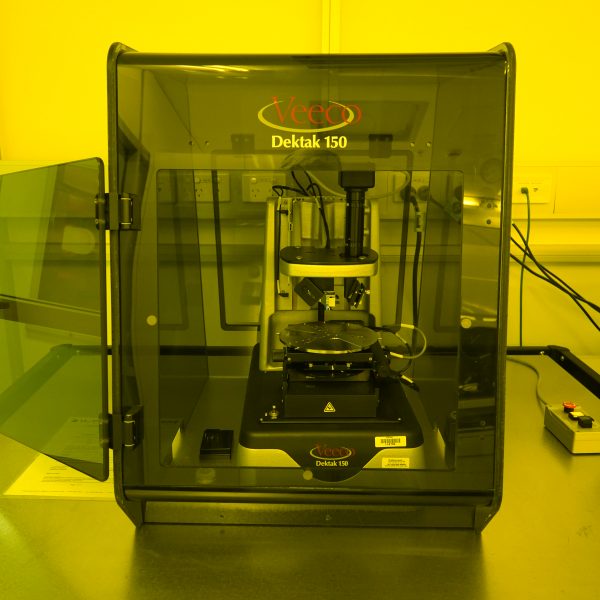

Dektak 150

| Location | UNSW – West Lab (White Area) |

| Scan Length Range | 55 mm |

| Data Points Per Scan | 60,000 maximum |

| Max. Sample Thickness | Up to 100 mm |

| Max. Wafer Size | 150 mm |

| Height Repeatability | 6Å, 1 sigma on 1 μm step |

| Vertical Range | 524 μm |

| Vertical Resolution | 1 Å max. (at 6.55 μm range) |

| Stylus Force | 1 – 15 mg |

| Sample Viewing | 640 x 480-pixel (1/3 in.-format) camera, USB; fixed magnification, 2.6 mm FOV (166X with 17 in. monitor) |

| Sample Stage | Manual X/Y/Θ, 100 x 100 mm X-Y translation,360° rotation, manual levelling |

| Stylus radius | 6.5 µm |

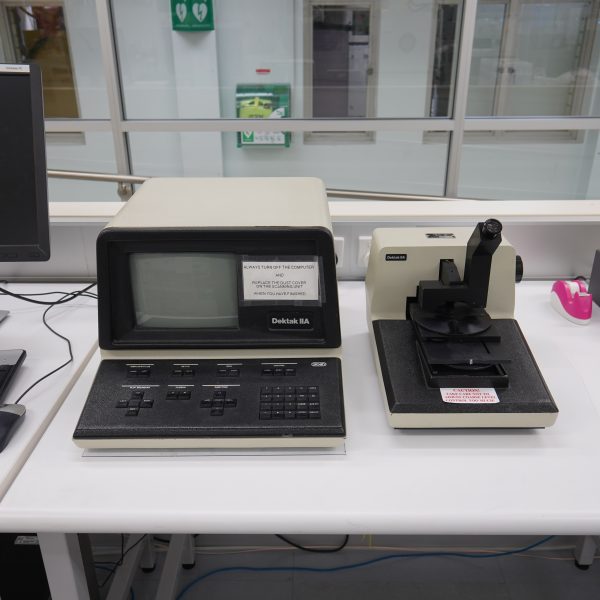

Dektak 2A

| Location | UNSW – West Lab (Grey Area) |

| Sample size | From small chips up to 4” |

| Max Scan Length | 30mm |

| Max depth | 30 micron |

Dektak 3030

| Location | UNSW – Lower East Lab (White Area) |

| Sample stage diameter | 165 mm |

| Max sample thickness | 45 mm |

| Max sample weight | 0.5 kg |

| Stylus tracking force | 1 – 40 mg |

| Sample stage translation | X Axis, +76mm (from center); Y Axis, 76mm |

| Sample stage rotation | Theta = 360° |

| Z – resolution | 1A/65 kÅ; 10A/655 kÅ; 20A/1310 kÅ |

| Leveling | Manual, 2-point or cursor levelling |

| Stylus diameter | 12.5 µm |

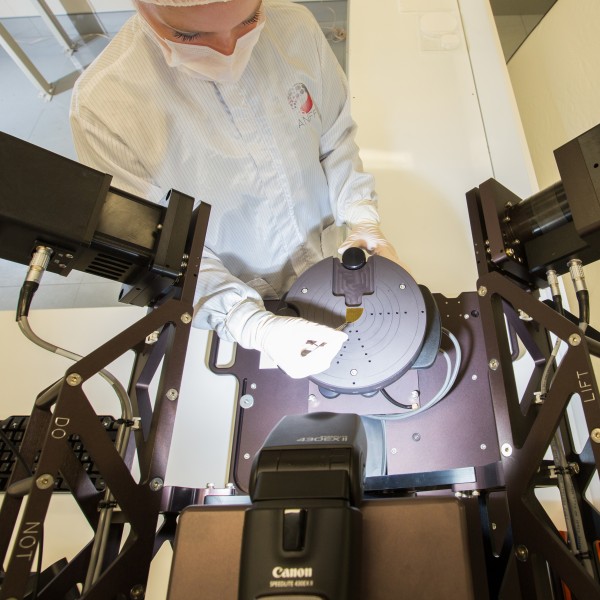

Dicing Saw ADT 7122 *

| Purpose | A spindle dicing system that offers customizable and/or full-automatic dicing solution |

| Location | RPF Lab 3021 |

| Material systems | Wafers, silicon, glass, ceramic |

| Scale / volume | Capable of cutting semiconductor wafers, silicon, glass, ceramic up to 6 inches |

| Specs / resolution | High accuracy up to 1µm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Die Bonder Fine Tech Lambda

| Purpose | The die bonder provides sub-micron precision die attach and advanced flip-chip packaging capabilities |

| Location | RPF Cleanroom |

| Material systems | Epoxy / adhesive; formic acid; thermo-compression; thermo-sonic bonding |

| Scale / volume | Heated stage accommodates up to 50mm x 50mm samples; maximum chip size for the bonder pick is 15mm x 15mm |

| Specs / resolution | Precision placement and alignment; thermo compression; ultrasonic or thermosonic bonding, formic acid, adhesive dispense module |

Dry Film Laminator Fortex FL-0305-01 *

| Purpose | Uniform resist coverage and an alternative to thick liquid resist spin coating; the material feed type is an automatic roll of film and pre-cut sheets |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Substrate material compatibility: wafers (silicon, glass, sapphire), brass, foils, steel, PCB |

| Scale / volume | Substrate thickness: up to 4mm; substrate size: from 5mm x 5mm up; 305mm x up to any desired length |

| Specs / resolution | Compatible with all dry film thickness range, but RPF stocks 50µm, 100µm, 200µm, and 500µm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

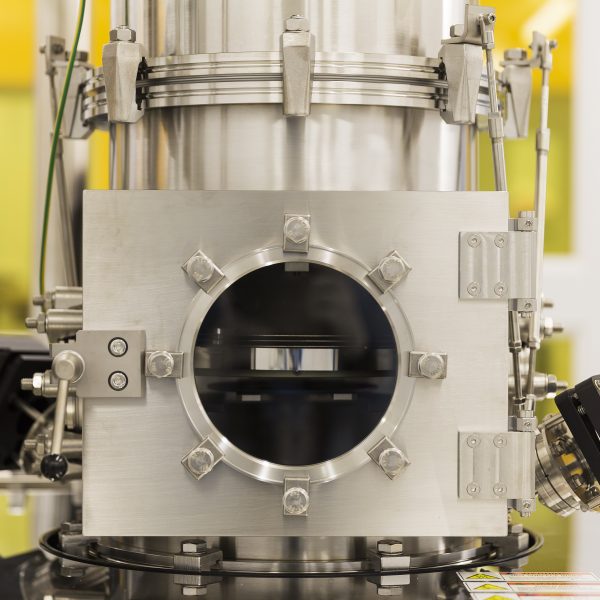

E-Beam Thermal Evaporator AJA ATC-1800-E *

| Purpose | A thin film deposition tool using e-beam or thermal process to deposit metal and oxides at nanometer scale thickness |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available materials include Ag, Al, Au, Cr, Ge, Ni, Ti, SiO2, TiO2, Ta2O, and Pt |

| Scale / volume | Small pieces to 6 inch substrates |

| Specs / resolution | Angled deposition capability; cooled rotating substrate holder; in-situ ion milling with Argon; controlled oxidation capability |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

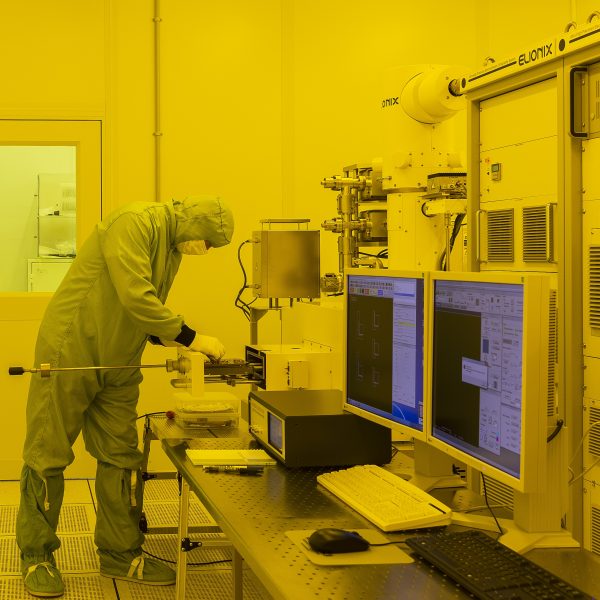

EBL Elionix ELS-F125 *

| Purpose | The Elionix electron beam lithography system has an acceleration voltage of 125kV and is capable of patterning high resolution features |

| Location | E-Beam Bay, RPF Cleanroom |

| Material systems | EBL resist coated wafers |

| Scale / volume | Accommodates small samples up to 6 inch wafers |

| Specs / resolution | 2nm beam diameter at 500pA beam current; dynamic focus and stigmatism adjustment; maximum 500um write field; field stitching error smaller than 20nm; overlay alignment better than 20nm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

EBL Spinner Wet Bench (ReynoldsTech)

| Purpose | Exhausted wet bench used for resist coating processes dedicated to electron beam lithography resists |

| Location | Wet Process Bay, RPF Cleanroom |

| Material systems | EBL resists |

| Scale / volume | Accommodates small samples up to 6 inch wafers |

| Specs / resolution | Includes two spinners dedicated to PMMA and CSAR / ZEP processes |

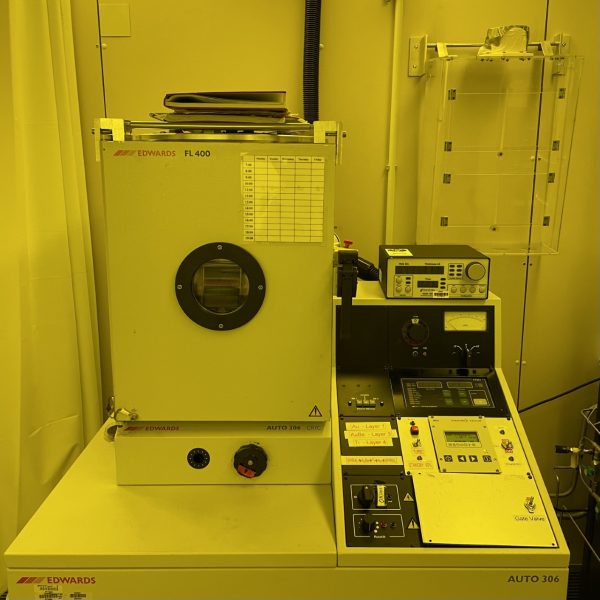

Edwards Auto 306 Thermal Evaporator (Aluminum SET)

| Location | UNSW – Lower East Lab (White Area) |

| Thin film material | Aluminium only |

| Gas | Oxygen, upper chamber for oxidation of Al only |

| Sample size | Up to 1 inch diameter (upper chamber) |

| Substrate material restriction | silicon compatible material only |

Edwards Auto 306 Thermal Evaporator (AuBe)

| Location | UNSW – Lower East Lab (White Area) |

| Thin film material | AuBe, Ti, Au |

| Base pressure | 9e-7 mbar |

| Sample size | Up to 3 inch in diameter |

| Substrate material restriction | Gallium arsenide compatible material only |

Edwards Evaporator

| Location | UNSW – South Lab (Test Area) |

| Maximum wafer size | 150 mm round |

| Throw | 400 mm |

| Boat contact size | 3/8” (~10 mm) |

| Maximum number of evaporator sources | 4 |

| Maximum power | 250 W |

| Additional process gases available | Ar, O2 |

| Other specifications | Glow discharge of process gases |

Edwards Sputterer

| Location | UNSW – South Lab (Tese Area) |

| Sample size | Up to 4” wafer |

| Target size | 4” (Single target) |

| Material available | Ti and Cr

Other materials by prior approval |

| Power sources | DC 10-300W and RF 10-300W |

| Process gases | Ar, N2 and O2 |

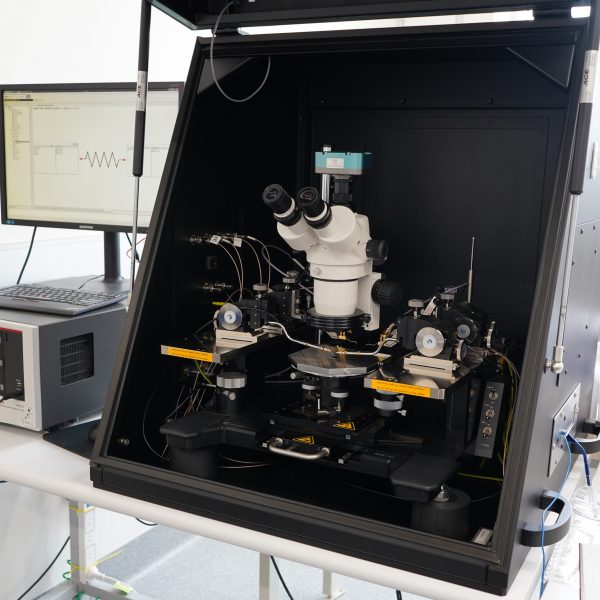

Electrical Probe Station Suss PM 5

| Purpose | 4 probe DC probe station for measuring electrical properties of materials and devices |

| Location | RPF Lab 3021 |

| Scale / volume | Substrate size up to 6 inch wafer |

| Specs / resolution | Can heat substrate up to 120°C during measurement |

Ellipsometer JA Woollam M2000 *

| Purpose | A metrology tool that measures the thickness & refractive index of thin films and multi-layered films using polarised light |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Thin films |

| Scale / volume | Small samples to 6 inch wafers |

| Specs / resolution | Measurement wavelength ranges from 200nm to 1000nm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Etch Spin Rinse Dryer (ReynoldsTech)

| Purpose | Automated batch wafer cleaning tool |

| Location | Wet Etch Bay, RPF Cleanroom |

| Material systems | Can batch process substrates in a cassette |

| Scale / volume | 2 inch, 4 inch, and 6 inch wafers; 4 inch and 5 inch photomasks |

| Specs / resolution | Can accommodate up to 6 inch wafers, interchangeable rotors |

F&S Bondtech 53XX BDA Bonder

| Location | UNSW – South Lab (Test Area) |

| Configuration | 25 μ |

| Bondhead Z: | 60mm; step of 1 μm |

| Standard work height | 70mm |

| Manipulator in X and Y: | 18x18mm complies |

| Two-channel ultrasonic generator | 100-105 kHz 2.5 – 5 W |

| Wire guide | 90 °, 2 “wire coil |

Lesker Thermal Evaporator

| Location | UNSW – Lower East Lab (White Area) |

| Thin film material | Ge, Ni, Ti, Au, AuGe, PdAu, Cr, Al, Co |

| Base pressure | 9e-7 mbar |

| Sample size | Up to 3 inch in diameter |

| Rotation | Angled evaporation with rotation |

FEI Sirion Electron Beam Lithography System

| Location | UNSW – Lower East Lab (White Area) |

| Wafer holder | Up to 2” |

| Maximum write area | Up to 1 mm x 1 mm per pixel |

| Pixel stitching accuracy | ~ 2 um |

| Smallest feature size | ~ 20 nm in ~20 um x 20 um pixel |

| SEM Imaging resolution | ~2 nm |

| Patterning software | NPGS |

FEI XL30 Electron Beam Lithography System

| Location | UNSW – Lower East Lab (White Area) |

| Wafer holder | Up to 2” |

| Maximum write area | Up to 1 mm x 1 mm per pixel |

| Pixel stitching accuracy | ~ 2 um |

| Smallest feature size | ~ 20 nm in ~20 um x 20 um pixel |

| SEM Imaging resolution | ~2 nm |

| Patterning software | NPGS |

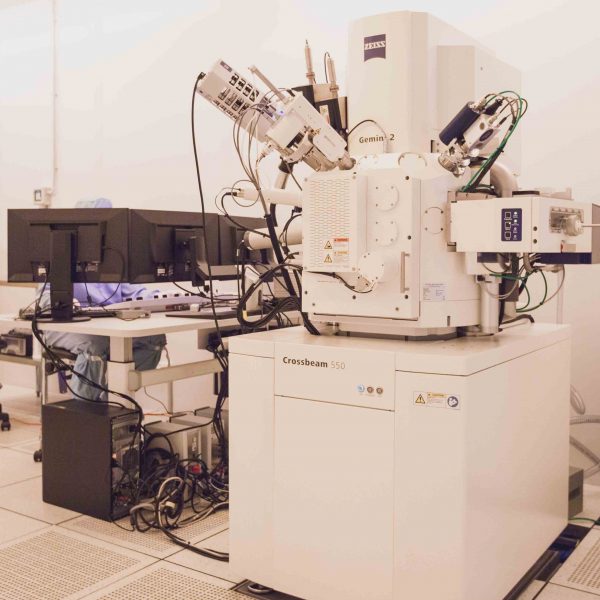

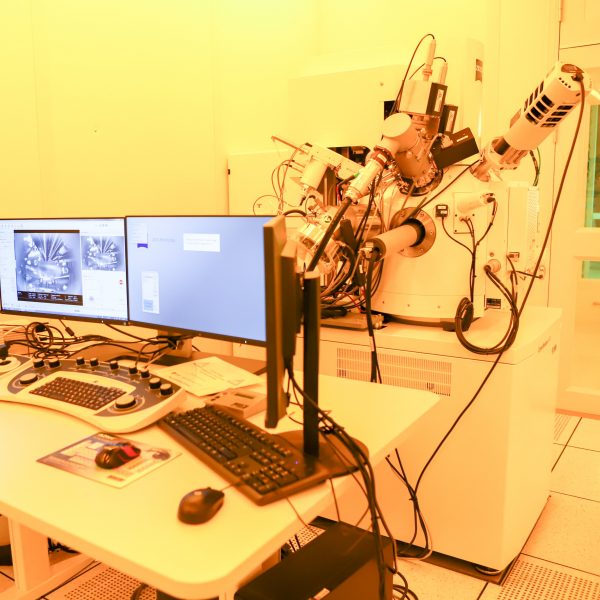

FIB-SEM Zeiss Crossbeam 550XL *

| Purpose | A multi-purpose platform that enables advanced Scanning Electron Microscopy imaging and analysis as well as Focus Ion Beam milling & deposition for cross-section profile inspection and other applications |

| Location | E-beam Bay, RPF Cleanroom |

| Material systems | It is fitted with options for elemental analysis, plasma cleaning, beam directed deposition and physical / chemical etching, diffraction based structural analysis, nano / micro manipulation, and electrical probing |

| Scale / volume | Imaging of non-conductive materials; elemental & crystallographic analysis and mapping @ ≥ 5nm; can accommodate samples as large as 150 mm wafers and 7 inch masks; 2nm image resolution; 4-10nm milling, etching, deposition |

| Specs / resolution | The FIB-SEM is a very versatile high performance tool for macro / micro / nano imaging, analysis, fabrication, manipulation, and characterisation; full analysis of any sample; in-situ milling / circuit edit / device modifications; metrology; charge compensated imaging and milling imaging; cross-sectioning; transmission imaging |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

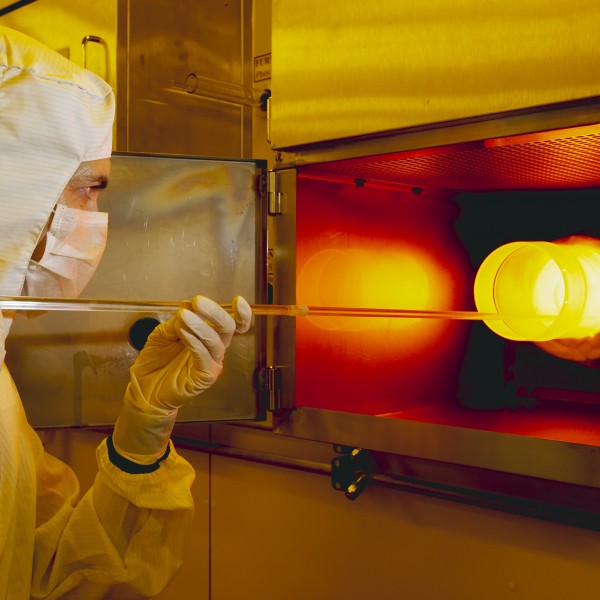

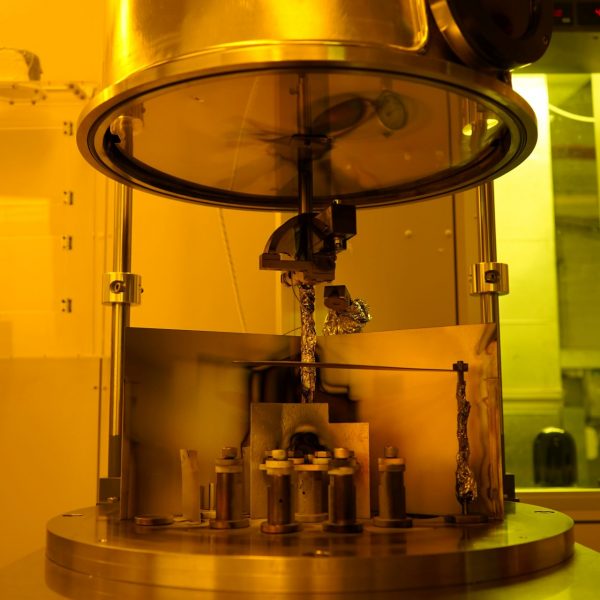

Fibre Draw Tower

| Purpose | Six meter dual sided Heathway fibre draw tower for primary and secondary drawing |

| Location | RPF Physics Lab 404 |

| Material systems | Polymers (e.g. Polyurethane, PMMA, Zeonex, Polycarbonate, TPU); soft glass (soda-lime, borosilicate, chalcogenide) |

| Scale / volume | Waveguides (solid, microstructure, air-core); co-drawn carbon elements and wires (e.g. ~500nm x 150nm wires); microstructure (internal air / fluidic channels) |

| Specs / resolution | Three furnace options for various preform sizes and temperature requirements; pressurised fibre coating system; tractor draw unit for capillary / cane drawing; pressurised drawing system; spinning motor for drawing spun fibres |

GaAs ULVAC MILA-5000 Annealing Furnace

| Location | UNSW – Lower East Lab (White Area) |

| Heating rate | 50°C/s high speed heating |

| Gas | Forming gas |

| Sample size | Up to 25 mm by 25 mm |

| Material restriction | GaAs compatible material only |

| Temperature Range | RT – 800 deg |

| Graphite plate option | Available |

General Purpose Reactive Ion Etcher

| Location | UNSW – West Lab (Grey Area) |

| Type | Parallel plate, rf |

| Target Area | 100mm |

| Substrate size | 100mm |

| Gases | Ar, O2, CF4, CHF3, SF6, (CH4 & H2 will be available soon) |

| Rf power | 200 W |

General Purpose Acid Wet Benches (ReynoldsTech)

| Purpose | Exhausted wet bench used for handling of general purpose acids |

| Location | Wet Etch Bay, RPF Cleanroom |

| Material systems | General acid chemicals; substrates |

| Specs / resolution | Includes two integrated stirring hotplates, heated and filtered process tank, and cascading tank for batch processing |

General Purpose Caustic Wet Bench (ReynoldsTech)

| Purpose | Exhausted wet bench used for handling of general purpose caustic based chemicals |

| Location | Wet Etch Bay, RPF Cleanroom |

| Material systems | General caustic / base chemicals; substrates |

| Specs / resolution | Includes integrated stirring hotplate, heated and filtered process tank, and cascading tank for batch processing |

GP Anneal Furnace

| UNSW – Upper East Lab (Grey Area) | |

| Tube size | 3” tube |

| Wafer size | Small chips up to 2” wafers |

| Gasses | N2, O2, forming gas |

| Temperature range | 200 – 1100C |

| Restrictions | General purpose |

GP ULVAC MILA-5000 Annealing Furnace

| Location | UNSW – Lower East Lab (White Area) |

| Heating rate | 50°C/s high speed heating |

| Gas | Forming gas |

| Sample size | Up to 25 mm by 25 mm |

| Material restriction | General purpose |

| Temperature Range | RT – 800 deg |

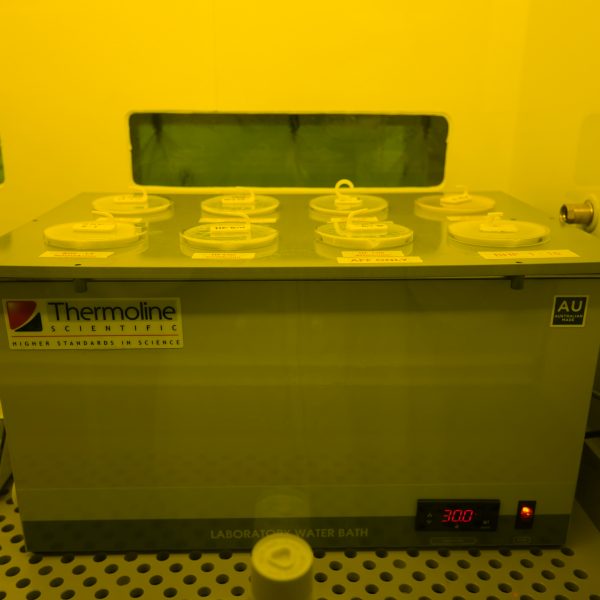

HF Constant Temperature Bath

| Location | Upper East Lab (White Area) |

| Constant temperature bath | 30C |

| HF solutions available – Si/SiO2 only | HF 1:10 (HF 49% : DI water),

BHF 1:5 (HF49% : Ammonium fluoride 40%), BHF 1:15 (HF49% : Ammonium fluoride 40%) |

| HF solutions available – general purpose (GP) | BHF 1:15 (HF49% : Ammonium fluoride 40%) |

HF Wet Bench (ReynoldsTech)

| Purpose | Exhausted wet bench used for handling of hydrofluoric acid |

| Location | Wet Etch Bay, RPF Cleanroom |

| Material systems | Hydrofluoric acid |

| Scale / volume | Small samples up to 4 inch wafers |

| Specs / resolution | Includes heated process tank and cascading tank for rinsing |

Hotplate Tower (ReynoldsTech)

| Purpose | Exhausted stacked hotplates for baking during solvent based processes |

| Location | Wet Process Bay, RPF Cleanroom |

| Material systems | Resist baking |

| Scale / volume | Accommodates small samples up to 6 inch wafers |

| Specs / resolution | Includes 6 hotplates dedicated to different temperature ranges – used for baking / outgassing purposes |

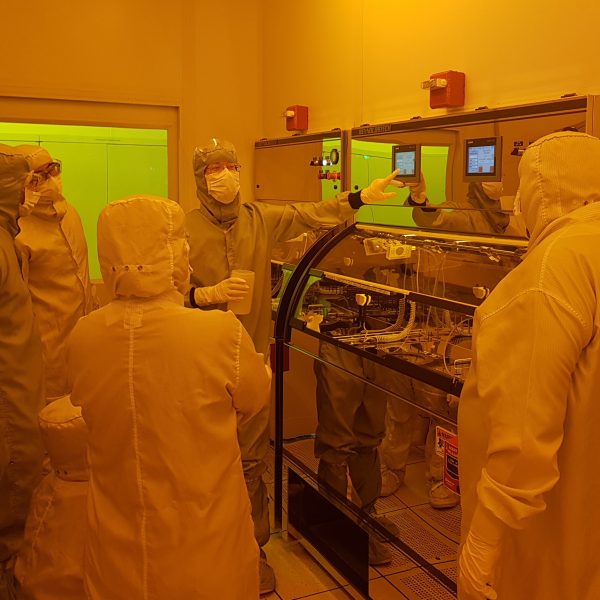

i-line Stepper ASML PAS 5500/100

| Purpose | A high throughput step-and-repeat projection lithography system that can pattern feature sizes down to 350nm |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Substrate material compatibility: wafers (silicon, glass, sapphire, etc.) with maximum thickness of 1.25mm |

| Scale / volume | Feature sizes down to 350nm; die size limited to 22mm x 22mm; 400nm; accommodates 4 inch and 6 inch wafers |

| Specs / resolution | 5x reduction in critical dimensions; well suited to demonstrating scalable batch processes on 6 inch wafers at low to medium volume production; high throughput wafer processing together with the SVG88 Rite Track for coating and development |

IBS Ion Implanter

| Location | UNSW – Far East Lab |

| Ion energy | 25-200 keV (single charge) |

| Ion current | Greater than 1 mA (typically ~100s uA) |

| Species | P, B, Sb, Ar, H, N |

| Substrate size | Max 6” wafer |

| Substrate carrier | 4 positions |

| Substrate angle to beam | Normal or 7° |

ICP RIE Oxford Plasmalab 100 *

| Purpose | A dry etching tool that etches Si and Si-based materials with an inductive-coupled plasma source in the process chamber |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available gases are SF6, C4F8, CF4, CHF3, supported with argon, oxygen, and helium |

| Scale / volume | Either 4 inch or 6 inch carrier |

| Specs / resolution | Cryo processes; pseudo Bosch; resist masks; in-situ optical monitoring for etch stop |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Jipelec RTA

| Location | UNSW – Upper East Lab (Grey Area) |

| Temperature range | 400 – 1050 °C |

| Substrates types allowed | Si wafer, with either P or B dopants only |

| Substrate sizes | Up to 4” |

| Pre-requisites | Wafers processed in-house only, full cleaned |

| Gases available | N2 |

K and S Al Wedge Bonder

| Location | UNSW – South Lab (Test Area) |

| Wire material | Al, 25 microns diameter |

| Bonding modes | 45 deg, manual, semi-automatic (Z-axis) |

Karl Suss Manual Wafer Scriber

| Location | UNSW – Upper East Lab (White Area) |

| Wafer size | Small pieces up to 100 mm |

| Scriber tip | Diamond tip |

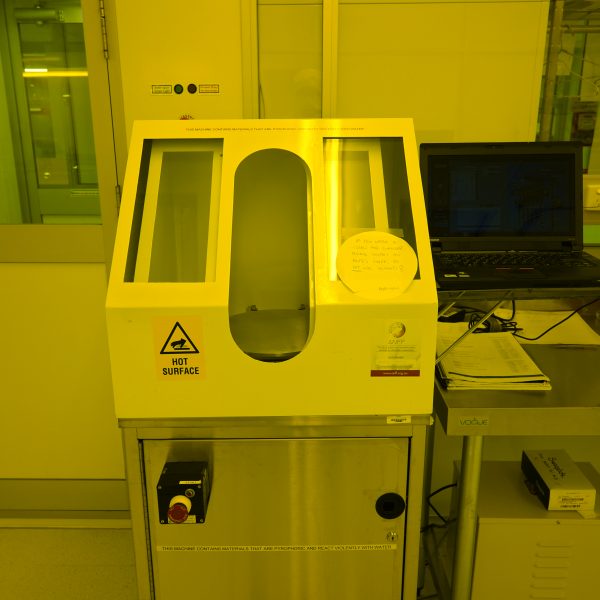

Lamp Annealer ULVAC MILA 5000 *

| Purpose | A desktop annealer capable of delivering high speed heating and cooling |

| Location | Wet Etch Bay, RPF Cleanroom |

| Material systems | Gases available N2 and forming gas |

| Scale / volume | Maximum wafer size 20mm x 20mm |

| Specs / resolution | Maximum temperature of 1000°C; 50°C/s high speed heating |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Laser Cutter Universal VLS3.60 *

| Purpose | The Universal VLS3.60 laser cutter is a high performance, floor-standing platform manufactured in the USA and comes with a powerful 50 watt CO2 laser system |

| Location | RPF Madsen Lab 224A |

| Material systems | The VLS3.60 laser cutter is gas assist capable and has been designed for high material throughput producing high accuracy parts. |

| Scale / volume | The machine has a materials processing area of 610mm x 305mm x 229mm |

| Specs / resolution | The machine is paired with Coreldraw2019 software for optimum design capability and ease of use; the VLS3.60 capable of cutting extruded acrylic sheet up to 12mm thickness |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

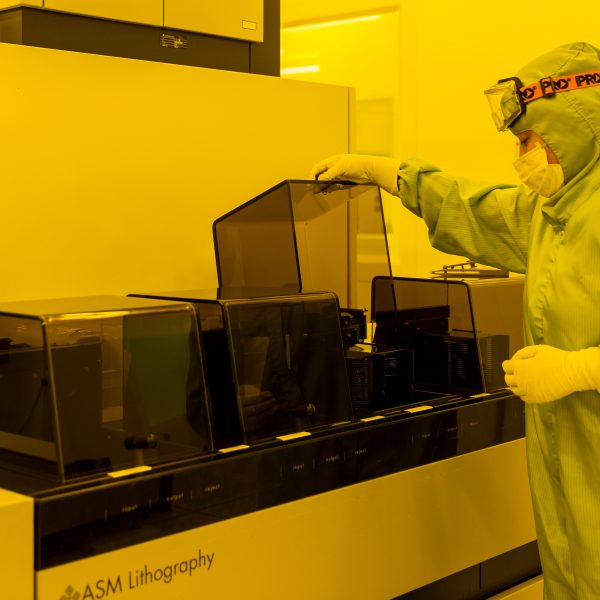

Laser Writer Heidelberg DWL 66+

| Purpose | Direct write laser lithography system capable of high resolution and grayscale patterning; UV laser direct-write system at submicron resolution for quick prototyping |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Photoresist coated substrates with up to 6mm thickness |

| Scale / volume | 375nm laser wavelength; accommodates up to 9 inch wafers; |

| Specs / resolution | 800nm; maximum write area 200mm x 200mm; multiple write modes – capable of achieving submicron features with highest resolution |

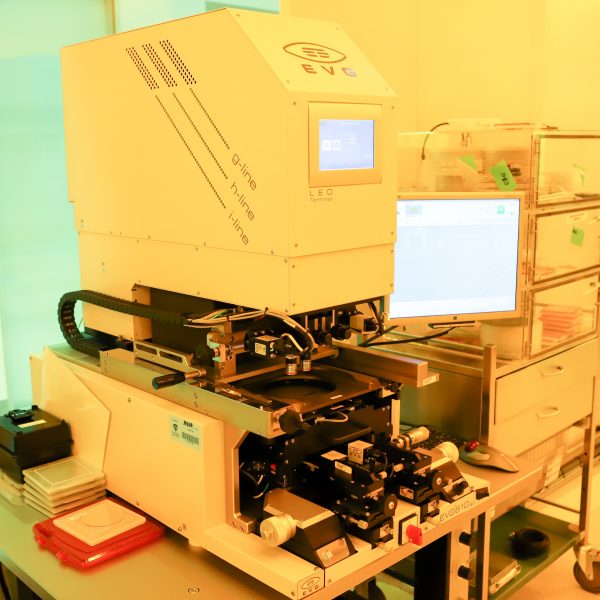

Mask Aligner EVG 610 *

| Purpose | A photolithography tool that supports top and back sides mask alignment and can pattern with feature size in micron; vacuum contact, soft contact, proximity exposure modes |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Photomasks and photoresist-coated substrates |

| Scale / volume | Photomask sizes: 4 inch, 5 inch, and 7 inch; substrate size: 2 inch, 4 inch, and 6 inch |

| Specs / resolution | Vacuum contact: 1 – 1.5um; soft contact: 1.5 – 3um; proximity: >3um |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

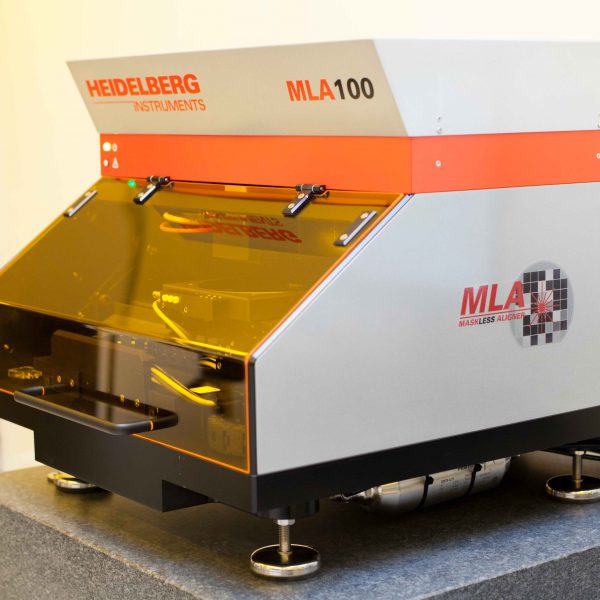

Maskless Aligner Heidelberg MLA100 *

| Purpose | A fast-speed maskless alignment photolithography tool that patterns feature size down to 2um; UV LED direct-write system for feature sizes at the micron level |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Photoresist coated substrates with up to 6mm thickness |

| Scale / volume | 365nm LED wavelength, fast writing speed; accommodates up to 6 inch wafers |

| Specs / resolution | 2um; maximum write area is 125mm x125mm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Microscope Nikon Eclipse LV100ND

| Purpose | A manual upright optical microscope with NIS Software and UV source |

| Location | Metrology Bay, RPF Cleanroom |

| Scale / volume | Can accommodate up to 150mm wafers |

| Specs / resolution | Combined reflectance / transmitted illumination with brightfield, darkfield, DIC, fluorescence, polarising, and phase-contrast; resolution limit is ≈300nm |

MJB3 Mask Aligner

| Location | UNSW – Lower East Lab (White Area) |

| Sample holder size | From small chips up to 3” wafers |

| Mask holder size | 4” square |

| Exposure modes | Vacuum, soft contact, hard contact |

| UV lamp spec | 365nm, 10 mW/cm2 |

Muffle Furnace

| Location | UNSW – West Lab (White Area) |

| Working volume | 3.5 L |

| Temperature range | 50 – 1000°C |

| Gases | N2 |

NanoFab Helium Ion Beam Zeiss *

| Purpose | A metrology and fabrication tool that enables imaging and fabrication at resolutions below what is possible in scanning electron microscopes |

| Location | RPF HIM Suite |

| Scale / volume | Sample sizes are limited to 50mm diameter and 30mm height |

| Specs / resolution | It is fitted with components for imaging non-conductive materials, nanoscale milling / deposition, and circuit editing; image resolution is ≈0.5nm, with ultimate limits of ≈1.5nm to 5 µm for milling / deposition |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

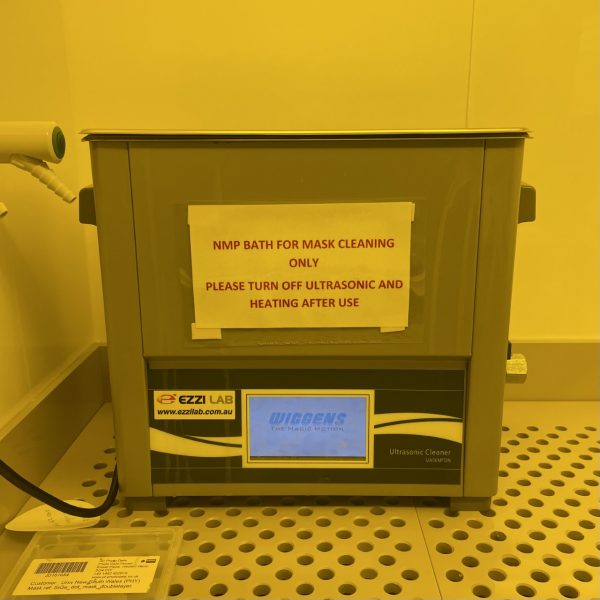

NMP Bath (photomask cleaning)

| Location | UNSW – Upper East Lab (white area) |

| Constant temperature bath | NMP at 80C |

| Other capabilities | ultrasonic |

| Mask size | up to 5” |

O2 Plasma Asher Glow *

| Purpose | A small plasma system that provides O2 plasma surface treatment such as wafer cleaning and photoresist / organic removal |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available gas is oxygen |

| Scale / volume | 10cm x 10cm samples |

| Specs / resolution | 50W RF power |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Olympus BH2 Microscope

| Location | UNSW – Lower East Lab (White Area) |

| Sample size | From small chips up to 4” |

| Objective magnifications | 5X, 10X, 20X, 50X, 100X |

| Features | Nomarski DIC Prism available on 50X objective |

Olympus BX51 Phase Contrast & Darkfield Microscope

| Location | UNSW – West Lab (White Area) |

| Sample size | From small chips up to 4” |

| Objective magnifications | 5X, 10X, 20X, 50X, 100X |

| Features | Darkfield & Phase Contrast |

Optical Microscopes Olympus DSX 510 *

| Purpose | A semi-automated upright digital optical microscope with LED light source |

| Location | Metrology Bay, RPF Cleanroom |

| Scale / volume | Can accommodate up to 150mm wafers with 100mm x 100mm addressable area |

| Specs / resolution | Reflectance illumination with brightfield, darkfield, DIC, and polarising; resolution limit is ≈300nm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Olympus DSX1000 Digital Microscope

| Location | UNSW – West Lab (Grey Area) |

| Features | BrightField, Oblique Illumination, Darkfield, MIX Illumination, Polarization, Differential Interference Contrast Motorized XY stage, Tilting Frame including motorized Z |

| Avail. Magnifications | Zoom 140X-1400X, 30mm working distance, N,A. 0.3 Zoom 560X-5600X, 4.5 working distance, N.A. 0.8 Zoom 42-420X (long working distance) |

Parylene Coater

| Location | UNSW – South Lab (Test Area) |

| Sample type | ALL (but contamination or hazardous ones) |

| Sample size | Up to 6” wafer (4 tiers substrates holder) |

| Adhesion promoter | Silane A-174 |

| Thickness range | 100 nm to 10um

(Thicker layer on request) |

| Dimer type | Parylene C |

PDMS Process Tools

| Purpose | Casting PDMS devices from a master to replicate features up to nanoscale |

| Location | RPF Lab 3021 |

| Material systems | Master material can be silicon, glass, aluminium, plastic, or polymer based substrate |

| Scale / volume | Throughput is up to one 4 inch device per hour |

| Specs / resolution | Can replicate features from 300nm and above |

PDMS Station

| Location | UNSW – Lower East lab (Grey Area) |

| Silicon Elastomer | Sylgard 184 (Dow Corning) |

| Thickness Range | PDMS membranes (10-500um)

PDMS blocks (1-10mm) |

Phosphorus Diffusion Furnace

| Location | UNSW – Upper East Lab (Grey Area) |

| Temperature range | 800 – 955 °C |

| Substrates types allowed | Si wafer, with either P or B dopants only |

| Substrate sizes | Up to 2” |

| Pre-requisites | Wafers processed in-house only, full cleaned |

| Gases available | N2 |

| Source wafers | Solid source |

Photo Spinner Wet Bench (ReynoldsTech)

| Purpose | Exhausted wet bench used for resist coating processes dedicated to thicker photolithography based resists |

| Location | Wet Process Bay, RPF Cleanroom |

| Material systems | Substrates to be coated with photoresist |

| Specs / resolution | Includes three spinners dedicated to positive, negative, and thick resist processes |

Picosun R-200 ALD system

| Location | UNSW – West Lab (White Area) |

| Materials | HfO2 and Al2O3 |

| Substrate | Small chips to 200mm |

| Temperature Range | 100C – 500C |

| Precursors | H2O, TMA and TEMAH |

Process Spin Rinse Dryer (ReynoldsTech)

| Purpose | Automated batch wafer cleaning tool |

| Location | Wet Process Bay, RPF Cleanroom |

| Material systems | Can batch process substrates in a cassette |

| Scale / volume | 2 inch, 4 inch, and 6 inch wafers; 4 inch and 5 inch photomasks |

| Specs / resolution | Can accommodate up to 6 inch wafers, interchangeable rotors |

Reactive Ion Etcher (Plasmatherm Vision) *

| Purpose | A compact reactive ion etching tool |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available gases are SF6, CF4, CHF3, supported with argon, oxygen, helium and nitrogen |

| Scale / volume | Accommodates 6 inch wafers |

| Specs / resolution | Optical emission spectroscopy endpoint detection |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Reactive Ion Etcher (South Bay RIE3000)

| Purpose | Reactive ion etch system dedicated to oxygen and argon plasma processes |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available gases are argon and oxygen |

| Scale / volume | Accommodates 6 inch wafers |

| Specs / resolution | Used primarily for resist and sample cleaning |

Solvent Develop Wet Bench (ReynoldsTech)

| Purpose | Exhausted wet bench used for solvent based development processes |

| Location | Wet Process Bay, RPF Cleanroom |

| Material systems | Solvents |

| Scale / volume | Accommodates small samples up to 6 inch wafers |

| Specs / resolution | Includes cold plate for cold development processes |

Solvent Lift-off Wet Bench (ReynoldsTech)

| Purpose | Exhausted wet bench used for solvent based metal lift-off and cleaning processes |

| Location | Wet Process Bay, RPF Cleanroom |

| Material systems | Substrates |

| Specs / resolution | Includes 3 heated ultrasonic tanks, an ambient filtered tank, and a cascading tank |

Spin coater (lower east)

| Location | UNSW – East lab (White Area) |

| Sample size | Small chips up to 4” wafers |

| Spin speed | Up to 8000 rpm |

Spin Coater (West white)

| Location | UNSW – West Lab (White Area) |

| Sample size | From small chips up to 6” |

| Max spin speed | 10k rpm |

| Max acceleration | 7300 rpm |

| Recipes | Multistep user programmable recipes |

Spin Dryer Delta 15

| Purpose | An automated single wafer substrate cleaning tool using DI water and compressed air |

| Location | Wet Process Bay, RPF Cleanroom |

| Scale / volume | 4 inch and 6 inch wafers; 4 inch, 5 inch, 6 inch, and 7 inch photomasks |

Sputter Coater DC Emitech K550

| Purpose | A small DC sputtering tool that can coat metal onto substrate |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available metal targets include Au, Ti, and Ni |

| Scale / volume | Small pieces to 6 inch substrates |

| Specs / resolution | Multiple small substrates for coating; coating uniformity up to 3.5 inch diameter |

Sputterer AJA ATC-2000-UHV *

| Purpose | A 5-gun DC/RF sputtering system that deposits metal and oxides at a controlled angstrom per second rate |

| Location | Plasma Etch & Deposition Bay, RPF Cleanroom |

| Material systems | Available materials include NbTi(N), SiO2, TiO2, ITO, Al, and Ti |

| Scale / volume | Small pieces to 6 inch substrates |

| Specs / resolution | Base pressure lower than 5 x10-8 torr; in-situ ion milling available; RF biased sample pre-clean available; substrate rotation with heating up to 800oC; ion milling / assisted deposition with Argon; controlled oxidation or nitration capability |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

STS ICP-DRIE

| Location | UNSW – West Lab (Grey Area) |

| ICP Power | 1800 W |

| Target power | 600 W |

| Gases | Ar, O2, CHF3, CF4, SF6, C4F8, He |

| Bosch process | YES |

| Substrate size | 4” |

| Electrostatic Clamp | YES |

Stylus Profilometer DekTak XT *

| Purpose | The Dektak XT profilometer is a stylus profiler capable of measuring step heights, film stress, and surface roughness |

| Location | Metrology Bay, RPF Cleanroom |

| Scale / volume | Can accommodate up to 150mm wafers |

| Specs / resolution | This tool is generally used for measuring 2D profiles and has a 0.1nm vertical resolution |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

AlphaPlasma Asher

| Location | UNSW – West Lab (White Area) |

| Sample size | From small chips up to 8” |

| Chamber diameter | 235 mm |

| Microwave power | 2.45 GHz adjustable between 50 – 1200 watts |

TPT HB10 Thermosonic Au Ball Bonder

| Location | UNSW – South Lab (Test Area) |

| Wire material | Au, 25 microns diameter |

| Bonding modes | Manual, semi-automatic (Z-axis) |

| Options | Laser marker, video camera |

Tystar Mini-Tytan Horizontal 3 Stack LPCVD Furnace System

| Location | UNSW – East Lab (Grey Area) |

| Max capacity | 50 x 8” wafers per run, though typically 25 x 6” or 4” |

| Tube #1 | Stoichiometric and Low-Stress nitride |

| Tube #1 gases | Dichlorosilane (DCS), Ammonia (NH3), Nitrous Oxide (N2O) |

| Tube #2 | P-doped or intrinsic polysilicon, amorphous silicon, dry oxide, low temp oxide P-doped or undoped. (Dopant gas currently unavailable) |

| Tube #2 gases | Silane (SiH4), Boron Trichloride (BCl3), Oxygen (O2) |

| Tube #3 | N-doped or intrinsic polysilicon, amorphous silicon, dry oxide, low temp oxide P-doped or undoped. (Dopant gas currently unavailable) |

| Tube #3 gases | Silane (SiH4), Phosphene (PH3), Oxygen (O2) |

| Temperature range | 400C – 950C (recipe dependent) |

| Pressure range | 100 mTorr – 500 mTorr |

UDOX Furnace

| Location | UNSW – Upper East Lab (Grey Area) |

| Temperature range | 800 – 1000 °C |

| Substrates types allowed | Si wafer, with either P or B dopants only |

| Substrate sizes | Up to 2” |

| Pre-requisites | Wafers processed in-house only, full cleaned |

| Gases available | N2, ultra-dry oxygen |

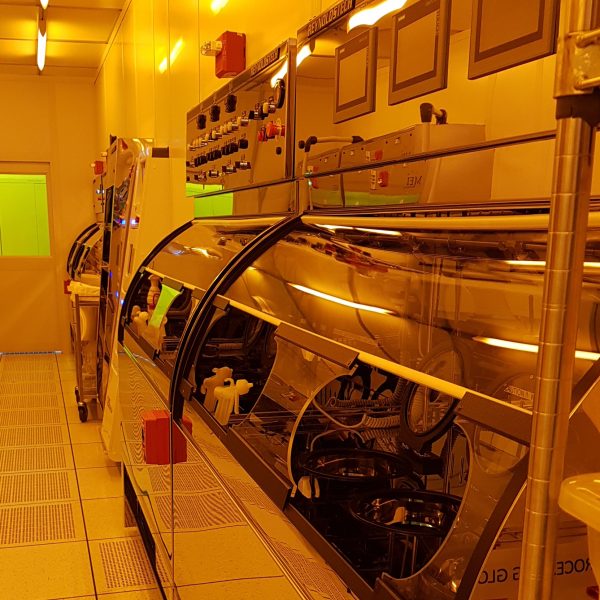

Wafer Track Processor Rite Track SVG88

| Purpose | A fully automated system for spin coating, HMDS application, baking, and development |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Auto dispense of resist – standard SPR660, and another type; MF26 developer |

| Scale / volume | Throughput of up to 60 wafers per hour; accommodates 3 inch, 4 inch and 6 inch wafers |

| Specs / resolution | Capable of running 25 wafers at a time; the system is well suited to batch scale production, providing high process performance and consistency in coating and development |

Wire Bonder TPT HB 100 *

| Purpose | The TPT wire bonder is capable of performing automatic and semi-automatic wire bonding with gold and aluminium wires |

| Location | RPF Lab 3021 |

| Material systems | Samples on PCB |

| Specs / resolution | Capable of manual, semi-auto and auto mode; wedge and ball bonding; deep access bond head |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

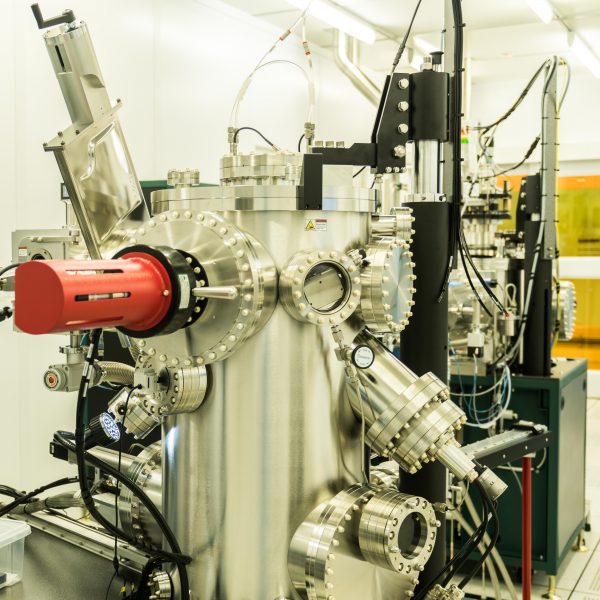

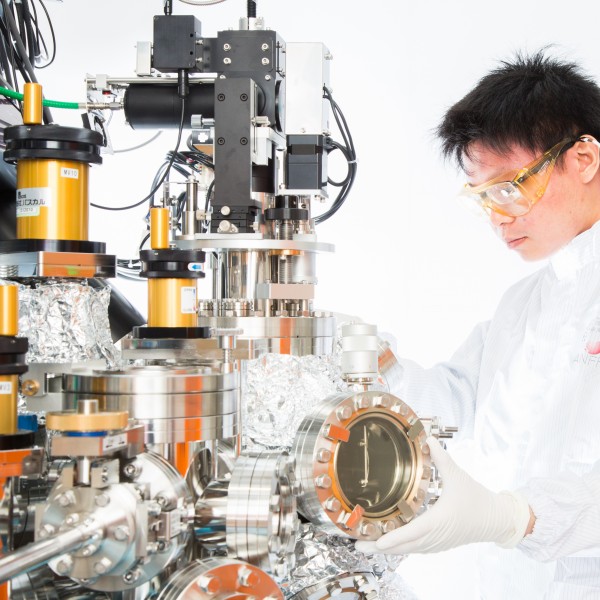

Veeco Gen930 III-V MBE

| Location | UNSW – South Lab |

| Purpose | epitaxial growth of III-V materials |

| Material systems | III-V semiconductors |

| Source materials | Ga, In, Al, As, Sb, Bi |

| Dopant materials | Si, Be |

| Scale/volume | wafers up to 75mm diameter |

Pascal pulsed laser epitaxial system

| Location | UNSW – South Lab |

| Purpose | materials scouting via epitaxial growth techniques |

| Substrate materials | wide range of substrate materials |

| Target materials | LiCoO3, Li3PO4, LiCoO2, VO2, VO3, MoO3, BNBTMn, LSMO, SrTiO3, LaAlO3, SrRuO3, SAO, LLTO, LAO, BTO, LCMO, STO, SrRuO3, NGO, ZMO, BCZT, BSZT |

| Scale/volume | Single wafers up to 25mm diameter |

| Specifications | 248 nm excimer laser. Max energy 400 mJ per pulse, avg power 8 W. Typically energy used ~100 mJ , In-situ reflective high energy electron diffraction (RHEED). Substrate temperatures up to 1000C |

Raith 150TWO Electron Beam Lithography System

| Location | UNSW – West Lab (White Area) |

| Sample size | From small chips up to 6” |

| SEM | ZEISS |

| Column | Gemini 0-30kV |

| Apertures | 7.5 10 15 20 30 60 120micron |

| FBMS | Available |

| Laser Height Sensing | Available |

| Focusing during exposure | By Column or by Stage Adjustment |

| Stitching Write Fields capability | Available |

| Smallest step size | 2nm |

| Beam shape | Spot |

| EBL resists available | Positive PMMA 950k, CSAR 9% and 18%,

negative Ma-N2403 |

| Detectors | In-lens and SE |

Karl Suss MA6 mask aligner

| Location | UNSW – West Lab (White Area) |

| Light source illumination | i-line (365nm) |

| Light Intensity | 10 mW/cm2 |

| Resolution | Down to 1 um

(depends on substrate size and flatness, resist type and thickness, and cleanroom conditions, and therefore, might vary for different processes) |

| Substrate size | Pieces from 5x5mm2, to 6” wafer |

| Photomask size | 4”, 5” and 7” |

| Exposure modes | Contact (Soft, Hard, Vacuum, Low vacuum)

Flood exposure |

| Alignment method | Top Side alignment (TSA)

Bottom Side alignment (BSA) |

Lesker PVD75 e-beam evaporator - Si-MOS compatible

| Location | UNSW – West Lab (Grey Area) |

| Sample type | Silicon Only – Si-MOS Compatible |

| Sample size | Up to 4” wafer |

| Material available | Ti, Al, Pt and Pd |

| Thickness range | 1nm to 500nm |

| Option | Plasma clean capability by Ar sputtering |

Lesker PVD75 e-beam evaporator - general purpose

| Location | UNSW – West Lab (Grey Area) |

| Sample type | ALL (but contamination or hazardous ones) |

| Sample size | Up to 6” wafer |

| Material available | Metals: Ag, Al, Au, Co, Cr, Cu, Fe, Ge, Ir, Nb, Ni, NiFe, Pd, Pt, Si, Sn, Ti

Oxides: Al2O3, CeO2, Fe2O3, In2O3, SiO2, TiO2, WO3 Other materials by prior approval |

| Thickness range | 1nm to 500nm (Thicker layer on request) |

HHV sputtering system

| Location | UNSW – West Lab (Grey Area) |

| Sputter gases | Ar, N2, O2 |

| Target materials (3” targets) | Ti, Al, Cr, Au, Cu, W, Nb, Ag, Si, ITO, Si3N4, SiO2, TiO2, ZnO |

| RF power | 600W max |

| 2000W max | |

| Chamber heating | Room Temp to 400 |

| Max sample size | 6” |

| Base pressure | Mid 10-8 mtorr |

Oxford Instruments Plasmalab 100 plasma-enhanced chemical vapour deposition system

| Location | UNSW – Upper East Lab (Grey Area) |

| Materials | SiO2, SiN, a-Si:H |

| Temperature range | 100 – 300C |

| Wafer size | Small chips up to 6” |

| Gasses | SiH4, NH3, N2O, N2, Ar, CF4 |

| Restrictions | no metals |

Oxford Instruments Plasmalab 100 Reactive Ion Etching System

| Location | UNSW – Upper East Lab (Grey Area) |

| Sample size | From small chips up to 6” |

| Gases | SF6, CF4, CHF3, O2, Ar,C4F8, N2 |

| RF power | 0-300W |

| Processes available | Si deep and shallow, SiO2, SiNx, Ge, Al2O3 |

| Process Pressure range | 5-250mTorr |

| Chiller temperature range | 0-80°C |

| DC range | 0-500V |

J A Woollam spectroscopic ellipsometer

| Location | UNSW – West Lab (Grey Area) |

| Modes | Spectral ellipsometry, transmission measurements |

| Wavelength range | 200 – 1000nm |

| Spot size | 3x3mm |

| Stage | No scanning |

| Wafer size | Small chips up to 6” |

| Software | WASE, Complete EASE |

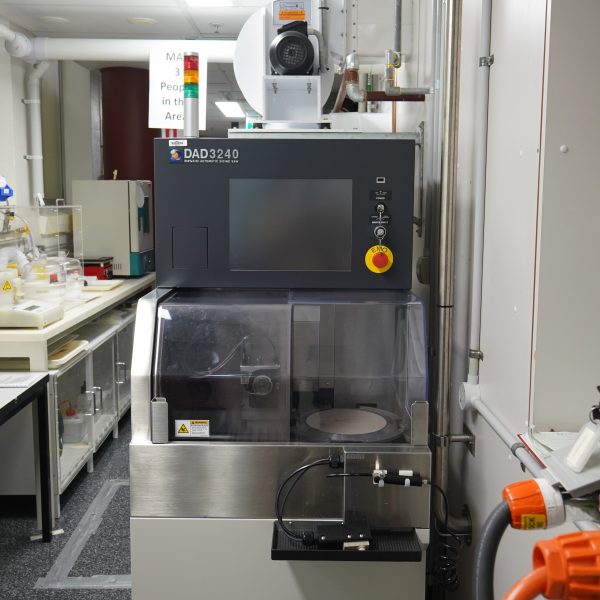

Disco DAD3240 dicing saw

| Location | UNSW – West Lab (Grey Area) |

| Table size | 8″ |

| Available blades | Si with 0.8mm exposure, and 0.035mm kerf |

| Si with 1.1 mm exposure, and 0.06mm kerf | |

| Glass up to 2mm thick with 0.2mm kerf | |

| Sapphire up to 2mm with 0.2mm kerf | |

| Quartz up to 2mm with 0.15mm kerf |