| Location | UNSW – Upper East Lab (White Area) |

| Wafer sizes | Up to 200 mm by 200 mm, 15 mm max. thickness |

| Light source | 365nm |

| Avail. resolutions | 0.5 µm, 0.7 µm, 1 µm, 2 µm and 5 µm at 365 nm |

| Greyscale levels | 256 levels |

Lithography

DMO MicroWriter ML3 Pro

Dry Film Laminator Fortex FL-0305-01 *

| Purpose | Uniform resist coverage and an alternative to thick liquid resist spin coating; the material feed type is an automatic roll of film and pre-cut sheets |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Substrate material compatibility: wafers (silicon, glass, sapphire), brass, foils, steel, PCB |

| Scale / volume | Substrate thickness: up to 4mm; substrate size: from 5mm x 5mm up; 305mm x up to any desired length |

| Specs / resolution | Compatible with all dry film thickness range, but RPF stocks 50µm, 100µm, 200µm, and 500µm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

EBL Elionix ELS-F125 *

| Purpose | The Elionix electron beam lithography system has an acceleration voltage of 125kV and is capable of patterning high resolution features |

| Location | E-Beam Bay, RPF Cleanroom |

| Material systems | EBL resist coated wafers |

| Scale / volume | Accommodates small samples up to 6 inch wafers |

| Specs / resolution | 2nm beam diameter at 500pA beam current; dynamic focus and stigmatism adjustment; maximum 500um write field; field stitching error smaller than 20nm; overlay alignment better than 20nm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Laser Writer Heidelberg DWL 66+

| Purpose | Direct write laser lithography system capable of high resolution and grayscale patterning; UV laser direct-write system at submicron resolution for quick prototyping |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Photoresist coated substrates with up to 6mm thickness |

| Scale / volume | 375nm laser wavelength; accommodates up to 9 inch wafers; |

| Specs / resolution | 800nm; maximum write area 200mm x 200mm; multiple write modes – capable of achieving submicron features with highest resolution |

Mask Aligner EVG 610 *

| Purpose | A photolithography tool that supports top and back sides mask alignment and can pattern with feature size in micron; vacuum contact, soft contact, proximity exposure modes |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Photomasks and photoresist-coated substrates |

| Scale / volume | Photomask sizes: 4 inch, 5 inch, and 7 inch; substrate size: 2 inch, 4 inch, and 6 inch |

| Specs / resolution | Vacuum contact: 1 – 1.5um; soft contact: 1.5 – 3um; proximity: >3um |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

Maskless Aligner Heidelberg MLA100 *

| Purpose | A fast-speed maskless alignment photolithography tool that patterns feature size down to 2um; UV LED direct-write system for feature sizes at the micron level |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Photoresist coated substrates with up to 6mm thickness |

| Scale / volume | 365nm LED wavelength, fast writing speed; accommodates up to 6 inch wafers |

| Specs / resolution | 2um; maximum write area is 125mm x125mm |

| * Not an ANFF-supported tool; access is available – refer to Access Fees schedule |

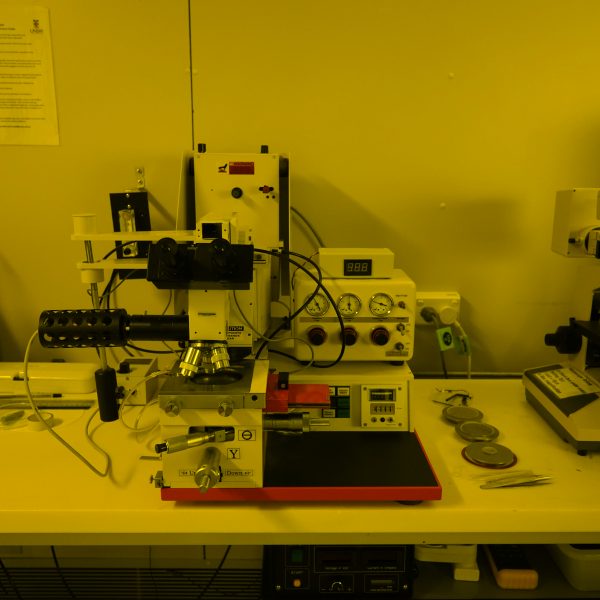

MJB3 Mask Aligner

| Location | UNSW – Lower East Lab (White Area) |

| Sample holder size | From small chips up to 3” wafers |

| Mask holder size | 4” square |

| Exposure modes | Vacuum, soft contact, hard contact |

| UV lamp spec | 365nm, 10 mW/cm2 |

NMP Bath (photomask cleaning)

| Location | UNSW – Lower East Lab (white area) |

| Constant temperature bath | NMP at 80C |

| Other capabilities | ultrasonic |

| Mask size | up to 5” |

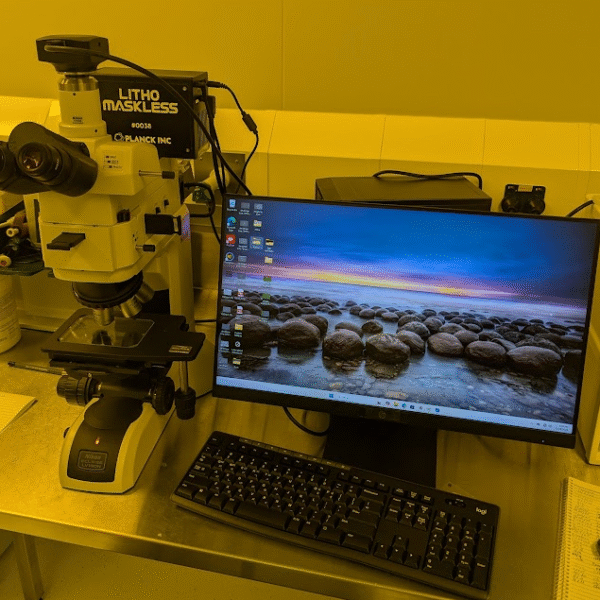

Planck Maskless Lithography System

| Location | UTS |

| Description | PLANCK maskless lithography system uses a 0.65″ 1920×1080 DMD and a 4 W UV source (365/385/405 nm) to project high-resolution patterns with feature sizes down to ~0.6–1.2 µm |

| Wafer size | TBC |

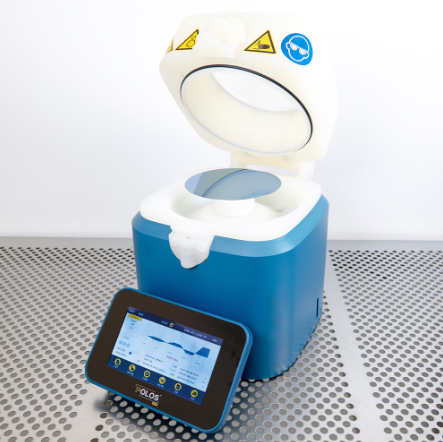

Polos Spin Coater

| Location | UTS |

| Description | Spin Coater |

| Wafer size | TBC |

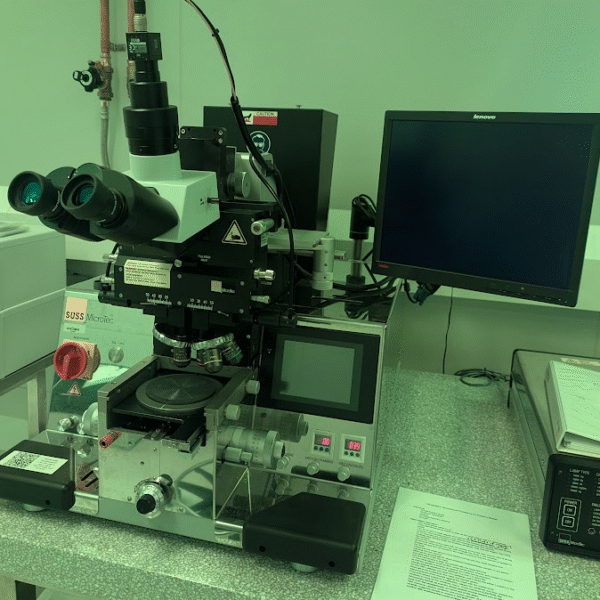

Suss Mask Aligner

| Location | UTS |

| Description | 365nm source, precision photolithography tool for high-accuracy optical alignment and controlled UV exposure |

| Wafer size | TBC |

Spin coater (lower east)

| Location | UNSW – East lab (White Area) |

| Sample size | Small chips up to 4” wafers |

| Spin speed | Up to 8000 rpm |

Spin Coater (West white)

| Location | UNSW – West Lab (White Area) |

| Sample size | From small chips up to 6” |

| Max spin speed | 10k rpm |

| Max acceleration | 7300 rpm |

| Recipes | Multistep user programmable recipes |

Spin Dryer Delta 15

| Purpose | An automated single wafer substrate cleaning tool using DI water and compressed air |

| Location | Wet Process Bay, RPF Cleanroom |

| Scale / volume | 4 inch and 6 inch wafers; 4 inch, 5 inch, 6 inch, and 7 inch photomasks |

Wafer Track Processor Rite Track SVG88

| Purpose | A fully automated system for spin coating, HMDS application, baking, and development |

| Location | Photo-Lithography Bay, RPF Cleanroom |

| Material systems | Auto dispense of resist – standard SPR660, and another type; MF26 developer |

| Scale / volume | Throughput of up to 60 wafers per hour; accommodates 3 inch, 4 inch and 6 inch wafers |

| Specs / resolution | Capable of running 25 wafers at a time; the system is well suited to batch scale production, providing high process performance and consistency in coating and development |

Raith 150TWO Electron Beam Lithography System

| Location | UNSW – West Lab (White Area) |

| Sample size | From small chips up to 6” |

| SEM | ZEISS |

| Column | Gemini 0-30kV |

| Apertures | 7.5 10 15 20 30 60 120micron |

| FBMS | Available |

| Laser Height Sensing | Available |

| Focusing during exposure | By Column or by Stage Adjustment |

| Stitching Write Fields capability | Available |

| Smallest step size | 2nm |

| Beam shape | Spot |

| Minimum feature size | < 20nm |

| EBL resists available | Positive PMMA 950k, CSAR 9% and 18%, negative Ma-N2403 |

| Detectors | In-lens and SE |

Raith Pioneer TWO

| Location | UNSW – West Lab (White Area) |

| Sample size | From small chips up to 2” |

| SEM | ZEISS |

| Column | Gemini 0-30kV |

| Apertures | 7.5 10 15 20 30 60 120micron |

| Laser Height Sensing | Available |

| Focusing during exposure | By Column or by Stage Adjustment |

| Stitching Write Fields capability | Available |

| Smallest step size | 2nm |

| Beam shape | Spot |

| Minimum feature size | < 8nm |

| EBL resists available | Positive PMMA 950k, CSAR 9% and 18%,

negative Ma-N2403 |

| Detectors | In-lens and SE |

Karl Suss MA6 mask aligner

| Location | UNSW – West Lab (White Area) |

| Light source illumination | i-line (365nm) |

| Light Intensity | 10 mW/cm2 |

| Resolution | Down to 1 um

(depends on substrate size and flatness, resist type and thickness, and cleanroom conditions, and therefore, might vary for different processes) |

| Substrate size | Pieces from 5x5mm2, to 6” wafer |

| Photomask size | 4”, 5” and 7” |

| Exposure modes | Contact (Soft, Hard, Vacuum, Low vacuum)

Flood exposure |

| Alignment method | Top Side alignment (TSA)

Bottom Side alignment (BSA) |